coolgadgets

3D Printing Notes

- DMCG 3D Printing slides

- 3D printing lecture notes

- 3D printing self-learning notes (requires Politemall access)

Manufacturing Processes

Motivations/Advantages

- Design freedom

- Faster production

- Customization

- Less waste

- many others

Materials

- PLA

- ABS

- PETG

- Nylon

- TPU

- HIPS

- glass

- ceramic

- carbon fiber

- metals: aluminum, steel, titanium, etc

- Food

- concrete

Simplify3D materials guide

Materials comparison chart

Constraints

- failure

- layer height

- time

- cost

- ventilation

- supports

- unsupported

- wall thickness

- dimensions

- anisotropy

- surface finish

- infill

- post-processing

Processes

- stereolithography (SLA)

- digital light processing (DLP)

- fused deposition modelling/fused filament fabrication

- ink-jet binder

- polyjet

- cut sheets

- selective laser sintering (SLS), selective laser melting (SLM)

- electron beam melting (EBM)

Machines

Service Bureaus

- Shapeways

- iMaterialise

- Sculpteo

- 3ERP

- Singapore

Materials Suppliers

File Formats

Design Software

- Onshape

- Fusion 360

- SolidWorks

- TinkerCAD

- SketchUp

- OpenSCAD

- Rhino 3D

Slicer Software

Mesh Editing

Downloadable Models

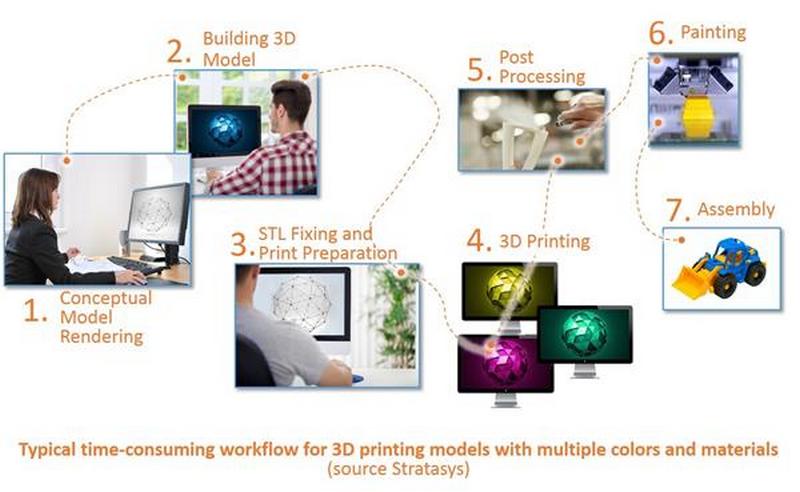

Workflow

- 3D Model (design, download, scan)

- Generate STL, OBJ, 3MF

- Slicer

- gcode

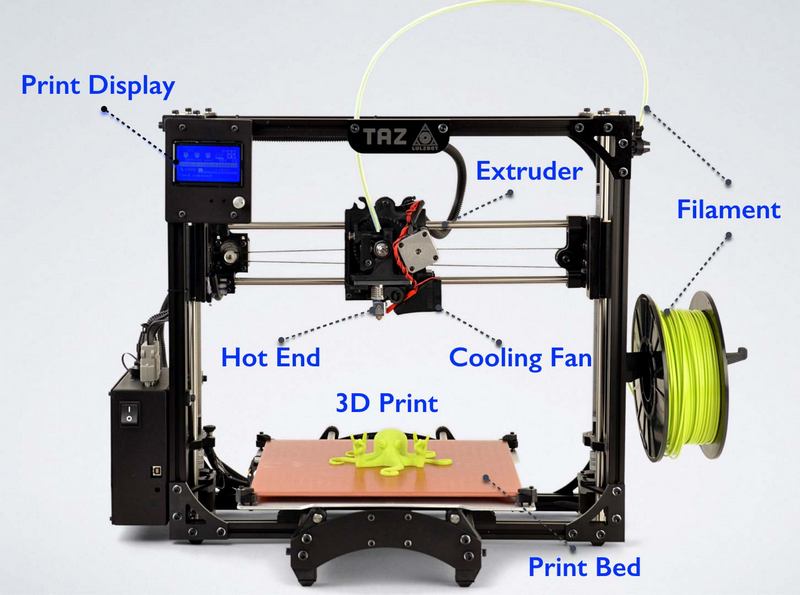

Parts of 3D Printer

- filament

- extruder

- build plate

- cooling fan

- display panel

- motor drives

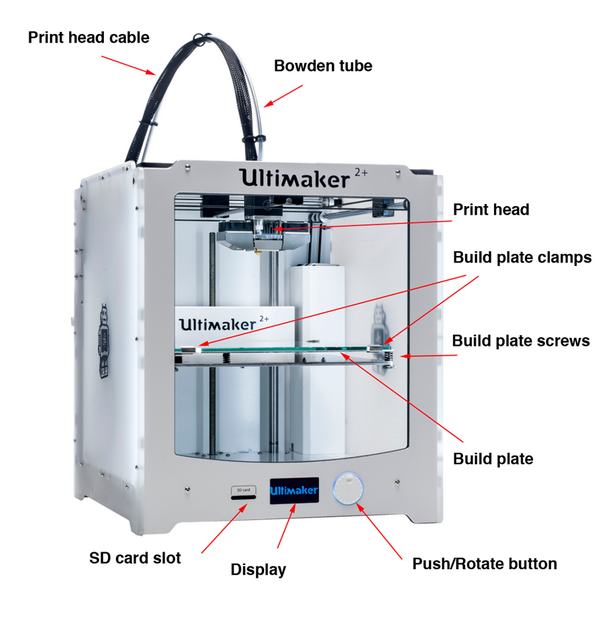

Ultimaker 2+ Parts

Guides

Recommended Cura settings

- Printer: Ultimaker 2+

- Material: PLA

- Nozzle: 0.4mm

- Layer height: 0.25mm (quick), 0.2mm (normal)

- Wall thickness: 0.8mm (min)

- Infill: 15 ~ 20% (normal)

- Print speed: 50 ~ 80 mm/s

- Support: none (preferred), touching buildplate (if require), everywhere (last resort)

- Bed Adhesion: none/skirt (preferred), brim (if required), raft (last resort)

Worksheet

Assignment 1

- Group: test the design rules for a 3D printer: bridging, overhang, infill density, clearance, etc

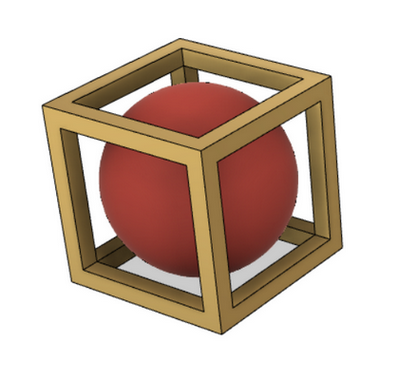

- Individual: design and 3D print an object (small, few cm3, limited by printer time) that could not be made subtractively

Assignment 2

- Sketch the profile for a fidget spinner toy and extrude it into a 3D model. 3D print the fidget spinner model. The fidget spinner uses the following parts:

- 608 bearing x1

- M8 hex nut x3

Asignment 3

- Download a silhouette for a chess piece, e.g. pawn

- Using the image that you have downloaded, sketch the profile of the piece and turn it into a 3D model using the appropriate 3D command (e.g. extrude, revolve). 3D print the chess piece.

For all assignments, you have to document the process, include your original CAD/design files and include a “hero” shot of your assignment