ep1000DigitalFab

3D Printing

Fablab 3D Printing notes

Manufacturing Processes

Motivations/Advantages

- Design freedom

- Faster production

- Customization

- Less waste

- many others

3D Printing Hall of Fame

Materials

- PLA

- ABS

- PETG

- Nylon

- TPU

- HIPS

- glass

- ceramic

- carbon fiber

- metals: aluminum, steel, titanium, etc

- Food

- concrete

Simplify3D materials guide

Materials comparison chart

Constraints

- failure

- layer height

- time

- cost

- ventilation

- supports

- unsupported

- wall thickness

- dimensions

- anisotropy

- surface finish

- infill

- post-processing

Processes

- stereolithography (SLA)

- digital light processing (DLP)

- fused deposition modelling/fused filament fabrication

- ink-jet binder

- polyjet

- cut sheets

- selective laser sintering (SLS), selective laser melting (SLM)

- electron beam melting (EBM)

Machines

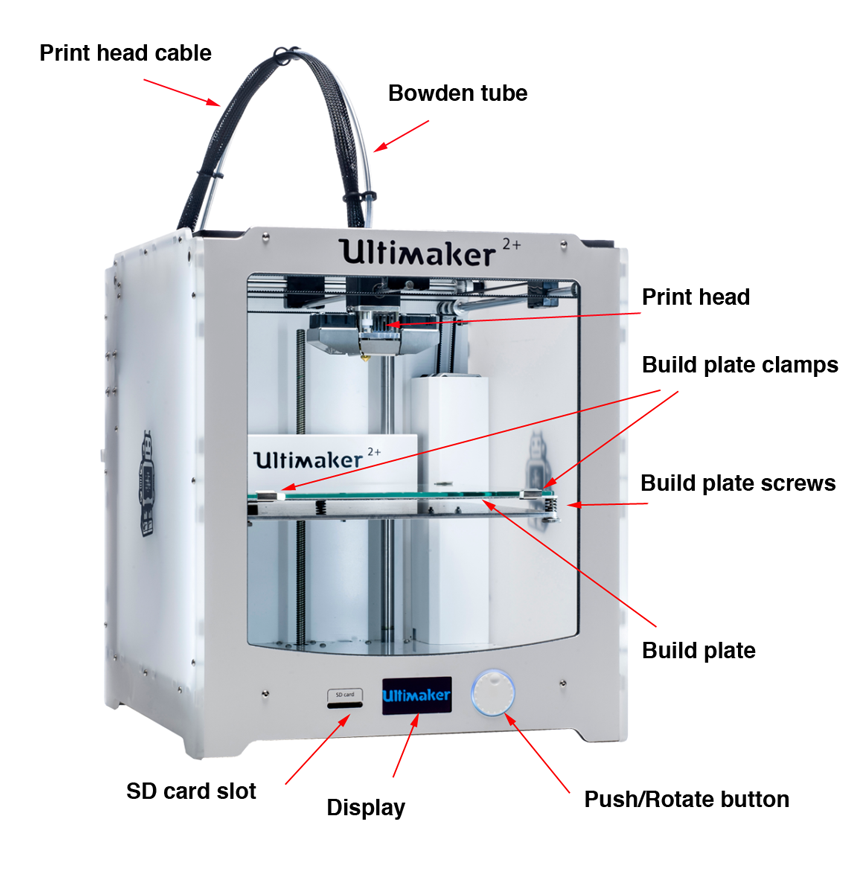

- Ultimaker

- Makerbot

- Prusa, parts

- Sindoh

- Creality Ender3

- Formlabs, parts

- Objet, parts

- 3D Systems

- Markforged

- 3-in-1 3D Printers

Service Bureaus

- Shapeways

- iMaterialise

- Sculpteo

- 3ERP

- Singapore

Materials Suppliers

File Formats

Design Software

- Fusion 360

- SolidWorks

- TinkerCAD

- SketchUp

- OpenSCAD

- Rhino 3D

Slicer Software

Mesh Editing

Downloadable Models

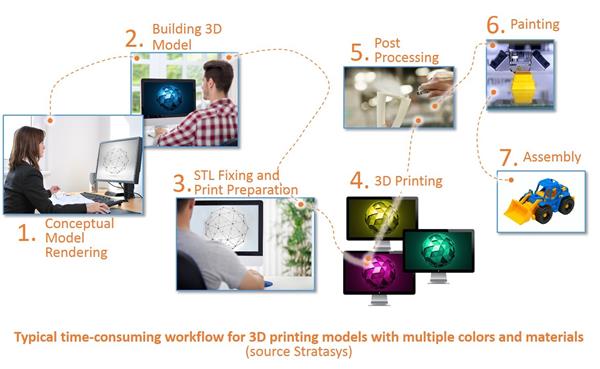

[Workflow]

- 3D Model (design, download, scan)

- Generate STL, OBJ, 3MF

- Slicer

- gcode

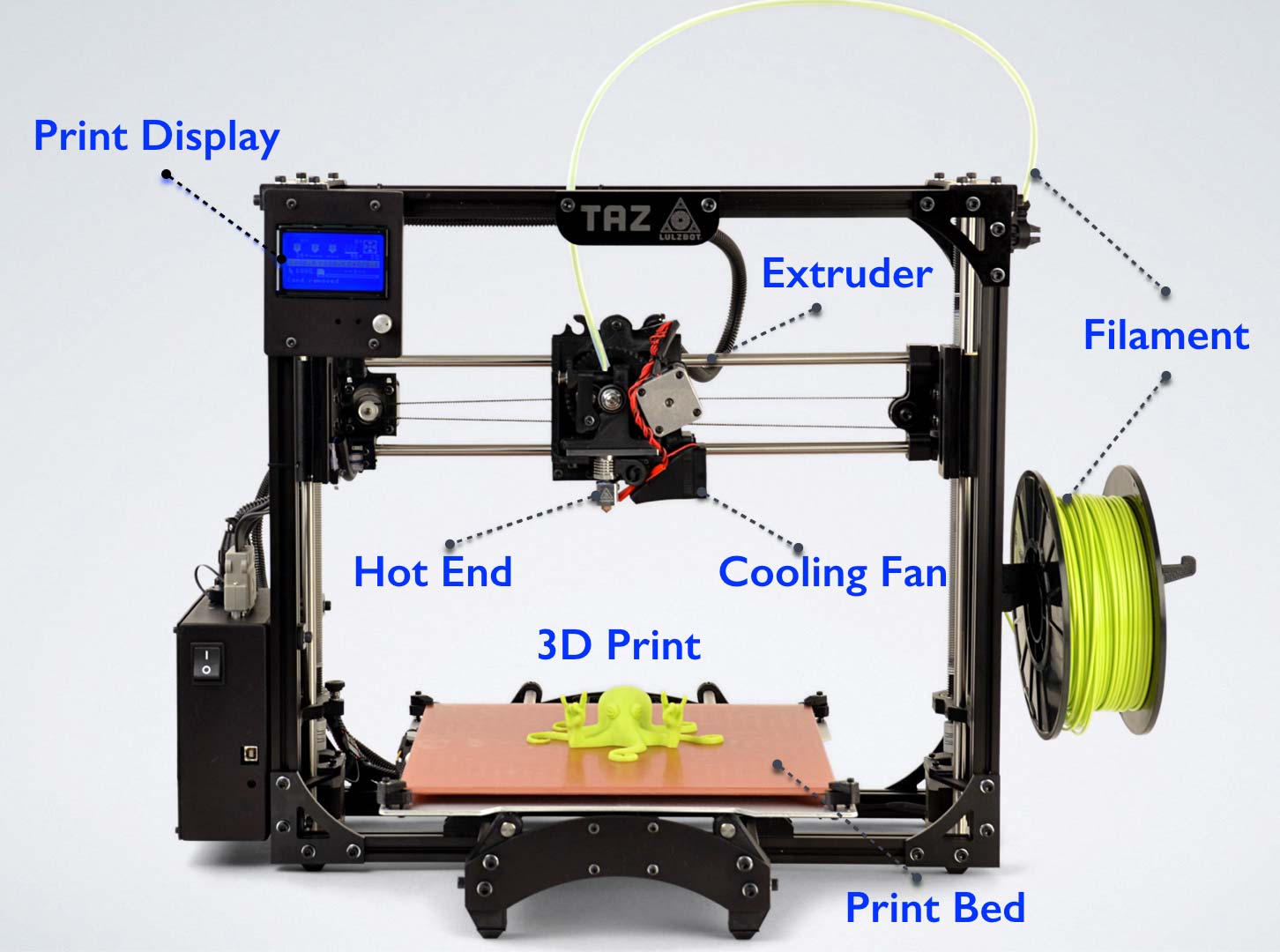

[Parts of 3D Printer]

- filament

- extruder

- build plate

- cooling fan

- display panel

- motor drives

Ultimaker 2+ Parts

Guides

Recommended Cura settings

- Printer: Ultimaker 2+

- Material: PLA

- Nozzle: 0.4mm

- Layer height: 0.25mm (quick), 0.2mm (normal)

- Wall thickness: 0.8mm (min)

- Infill: 15 ~ 20% (normal)

- Print speed: 50 ~ 80 mm/s

- Support: none (preferred), touching buildplate (if require), everywhere (last resort)

- Bed Adhesion: none/skirt (preferred), brim (if required), raft (last resort)

Worksheet

Assignment

- Group:

- test the design rules for a 3D printer: bridging, overhang, infill density, clearance, etc

- 4 members to a group, each person to design model to test one feature of the 3D printer

- Document your contribution & link to the pages of your other group members

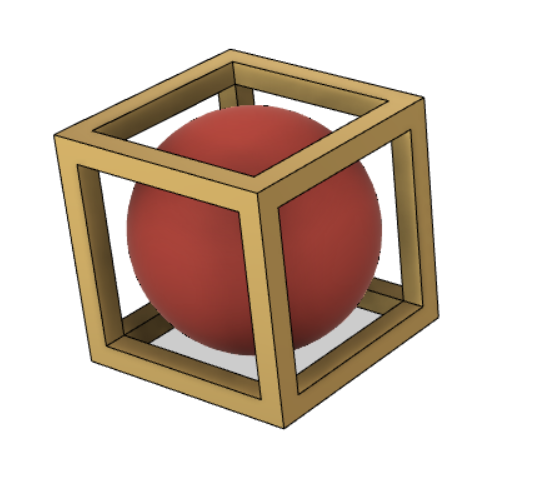

- Individual: design and 3D print an object (small, few cm3, limited by printer time) that could not be made subtractively

For all assignments, you have to document the process, include your original CAD/design files and include a “hero” shot of your assignment

Example of Individual Assignment